Material Science

The development of new coatings, dispersions, inks and functional polymers is an important materials science topic.

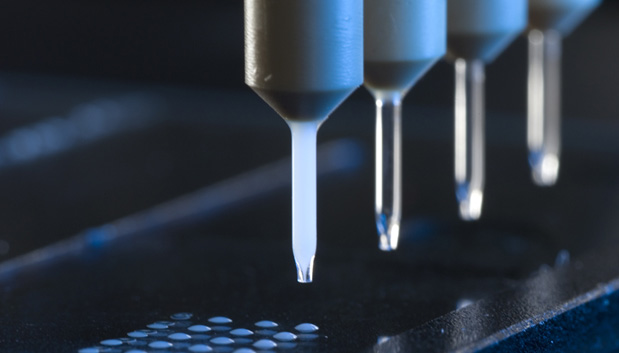

Industrial Applications

Our products are found in several production processes, e. g. material deposition of oils (lubrication of hard drive motors and watch parts, minimal lubrication for drilling), adhesives (bonding of micro-parts and optics) and mercury (lamp production). read more

Company

microdrop Technologies offers precise non-contact microdispensing equipment with high repeatability for a variety of application started from R&D up to Life Science and Industrial Applications. We are specialized in tailor-made solutions in close collaboration with our customer.

Services

We offer a number of lab and engineering services to find the best solution for the application demands of our customers. Starting from a liquid test to find out if the liquid is appropriate; an application test will be the further step to find the optimized solution for the desired production process.

Downloads

Here a simple and clear overview of our product details as well as application sheets can be downloaded with several technical information. Publications and customer area can be found as well as an access to PC visit for online-support and desktop sharing.